As devices come to be progressively complex and small, the need for premium PCB assembly manufacturers has actually surged. When going over PCB assembly, it is crucial to recognize not only the procedures involved however additionally how to pick the best PCB assembly manufacturer to ensure that the last item satisfies the highest possible standards of top quality and reliability.

The PCB assembly procedure includes a number of vital steps, consisting of assembly, prototyping, and layout. Creating a PCB involves producing a schematic layout that describes exactly how the numerous components will get in touch with each various other. This is a vital action, as errors in the design can lead to defective items. As soon as the design is completed, a model is commonly created to evaluate performance. After strenuous screening and necessary iterations on the prototype, manufacturing can begin.

One vital aspect of PCB assembly is surface area install technology (SMT), an approach that has revolutionized the production process by permitting for the installing of components straight onto the surface of the PCB. An additional typical method is through-hole innovation, where components are put into holes on the PCB and soldered in place.

When selecting a PCB assembly manufacturer, numerous factors have to be taken into consideration to ensure the best feasible outcome. A trustworthy manufacturer should have a tested track document of delivering premium products and excellent consumer solution.

An additional critical facet to evaluate is the manufacturer's capacities and modern technology. The most effective PCB assembly suppliers stay at the leading edge of innovation, providing advanced production processes and tools. The most recent machinery can dramatically improve the accuracy and rate of PCB assembly, inevitably making certain a better final product. The capability to take care of both low-volume and high-volume production runs is also an important attribute, as it supplies flexibility based on your specific demands. Additionally, manufacturers that spend in study and growth are a lot more most likely to adopt ingenious methods that can benefit your job.

Cost is another crucial factor to consider when choosing a PCB assembly manufacturer. It is sensible to obtain quotes from several suppliers and contrast not just the prices yet additionally what is included in each quote.

Lead time is additionally a crucial aspect to take into consideration. In today's fast-paced market, the capability to supply quickly can offer a considerable affordable advantage. It is vital to go over timelines ahead of time and have a clear understanding of the manufacturer's capacity to satisfy due dates. Hold-ups in assembly can have plunging results on product launches and supply chain management, which can eventually affect a firm's success.

As soon as an appropriate PCB assembly manufacturer has been selected, the cooperation should start with open interaction. Producers that are prepared to function very closely with clients to deal with concerns or make improvements demonstrate a reliable collaboration.

Making sure the high quality of the PCBA should be a leading priority throughout the process. Quality assurance steps should remain in place from the very early phases of assembly, including examinations, testing, and verification procedures. Using automated optical inspection (AOI) can aid catch issues that may not be visible to the nude eye, while functional screening can confirm that the constructed PCB carries out properly in real-world problems. The best makers will have rigid quality control processes and procedures to decrease errors and make certain a premium last product.

Fads such as miniaturization, raised intricacy, and the need for customization are driving innovations in PCB design and assembly processes. Staying updated on these developments allows a company to choose a PCB assembly manufacturer that does not just meet existing demands yet is additionally prepared for future needs.

Sustainability is ending up being a progressively crucial element of electronics manufacturing. As consumers and businesses alike come to be a lot more ecologically mindful, dealing with a PCB assembly manufacturer that prioritizes eco-friendly procedures can boost your brand name's credibility. This can include using lead-free solder, reusing programs, and accountable waste administration practices.

When going over PCB assembly is the potential for recurring assistance and service after the assembly is full, one more vital factor to consider. A high quality manufacturer does not simply supply the put together PCB and leave; they must be offered for assistance with any type of issues that might occur post-delivery. Whether it's repairing, repair services, or upgrades, having a relied on partner that can provide recurring support can be invaluable in keeping the longevity and efficiency of electronic items.

Looking ahead, welcoming technological improvements and fostering solid relationships with PCB assembly makers will certainly be essential to doing well in the fast-evolving electronics landscape. As market needs continue to move, firms that prioritize pcb assembly high-grade assembly processes, advancement, and a solid partnership with their makers will stand apart. The merging of emerging technologies, consumer assumptions, and sustainability will define the future of PCB assembly. It is essential that businesses stay active and receptive to these changes, ensuring they can adjust their methods to take benefit of brand-new opportunities.

In conclusion, browsing the world of PCB assembly requires a detailed understanding of the manufacturing procedure, a tactical approach to picking the best PCB assembly manufacturer, and a commitment to top quality and development. Hence, selecting to function with a respectable PCB assembly manufacturer is not just a technological decision; it is a calculated business option that can propel a brand name towards long-lasting success.

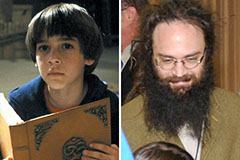

Barret Oliver Then & Now!

Barret Oliver Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Kane Then & Now!

Kane Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!